Emc test report что это

EMC Testing

Electromagnetic compatibility (EMC) refers to the ability of a technical device not to disturb other devices by electrical or electromagnetic effects or to be disturbed itself.

In an EMC test, the so-called immunity to interference and the emitted interference of devices are tested in particular. Because international legislators as well as manufacturers and distributors themselves specify a wide range of limits for the immunity and emitted interference of technical equipment, EMC testing is essential for their market launch.

Regulatory EMC Testing at CETECOM

We carry out EMC testing on the basis of various internationally harmonized EMC standards. Our test reports are recognized by official bodies and regulatory authorities around the world. This applies among others to:

Our testing services cover many common EMC requirements. Among others, the following guidelines should be mentioned here:

Customer-specific EMC Testing

In addition to the regulatory EMC testing, which is often necessary for the approval of your products, we also offer tailor-made EMC testing. This enables us to define and perform tailored EMC performance test procedures according to customer requirements. The tailored EMC test services include

Automotive EMC

We hold various accreditations to perform EMC testing on vehicles. CETECOM is, for example, appointed as technical service EMC. In addition, we have the corresponding E1 approval of the Kraftfahrt Bundesamt (KBA) for EMC test services according to UN-R 10 series of amendments 05 and 06 (appendices 7-10 and 17-22). In addition, we are also recognized for EMC test services by the authority in Luxembourg (SNCH) for E13.

Furthermore, we offer various EMC testing according to the specifications of car manufacturers. Among them:

EMC Testing for medical technology

We are accredited by the ZLG, the Central Authority of the Federal States for Health Protection with regard to Medicinal Products and Medical Devices, to perform EMC testing for technical medical devices.

Guidelines and standards in this context:

Thus we can offer EMC test services for electrical medical devices.

EMC for industrial products / mechanical engineering

Directive 2006/42/EC (Machinery Directive) regulates a uniform level of protection for the prevention of accidents involving machinery and partly completed machinery when it is placed on the market. This also includes EMC testing, which we can carry out either in our EMC measuring halls or in the form of on-site tests.

Electromagnetic environmental compatibility

Electromagnetic environmental compatibility (also called electromagnetic compatibility to the environment, EMCE) refers to the compatibility of the immissions of electromagnetic fields (EMF) to the environment, especially to humans. It defines limit values to ensure safety and prevent possible damage to health.

In our tests we cover frequency ranges between 0 Hz and 6 GHz – in individual cases also higher frequencies – for EMCE measurements of electric fields. For magnetic fields, frequencies up to 250 MHz are recorded and evaluated. Thus we test, for example:

Emc test report что это

In this section of the guide, we’re going to dig into an important part of preparing for EMI/EMC testing: emissions (EMI) pre-compliance testing and equipment.

You’ll learn about various options for test equipment, what an ideal test site looks like and what you’ll want to avoid with test equipment purchases.

EMC Pre-Compliance vs. EMC Troubleshooting Equipment

Some EMC test equipment claims to be ‘pre-compliance’ equipment when it’s actually only useful for EMC troubleshooting. As an example, a near field probe is good for tracking down an emission source and isolating the frequency of the emission, but it’s next to useless for telling you whether that emission will be a problem at an EMC test lab.

EMC test labs go to great lengths to create a test site that provides accurate field strength measurements. Despite their investment of tens or hundreds of thousands of dollars in test equipment and facilities, they can still only barely meet the acceptable error budget, which is +/- 4dB from an ‘ideal’ test site.

Often FCC registered test sites struggle to even meet this error budget as outlined in this ‘elephants in the test room’ webinar.

You typically won’t be able to get anywhere near +/- 4 dB of an ideal measurement using troubleshooting EMC equipment. The error may be closer to +/- 40 dB which is no good for working out whether you’re going to pass or fail at an EMC test lab.

So when we’re choosing emissions pre-compliance test equipment and making emissions measurements, we need to keep this error budget in mind. If we can be within +/- 4 dB of an ideal site, then we’re doing as well as a full compliance EMC test lab. To do that, you’re going to need a full compliance setup, which we’ll get into below.

Without investing in a full compliance setup, a more modest goal might be to get within +/- 10dB of an ideal site.

If we factor in a margin of 10 dB with our pre-compliance measurements, we could get a very good idea of whether we’ll pass or fail at a test lab.

EMC Troubleshooting

EMC troubleshooting equipment like near field probes are good for isolating RF sources and frequencies. You can make reasonable ‘relative‘ measurements, but not so good ‘absolute’ measurements.

EMC Pre-Compliance Equipment

Good EMC pre-compliance equipment is able to either measure directly or extrapolate to ‘absolute’ field strength values in the far field (at 3m or 10m measurement distances typically).

Near Field vs Far Field Measurements

When you’re measuring in the near field, it’s almost impossible to accurately extrapolate to an absolute field strength value in the far field because the relationship between the E (electric) and H (magnetic) fields are complex.

In the near field, there are strong inductive and capacitive effects from the PCB/system structures that are behaving like antennas, which causes the fields to behave unlike far field radiation fields.

Antenna Separation

At an FCC listed/accredited measurement facility, the separation between the equipment under test (EUT) and the measurement antenna is typically a minimum of 3 meters, but preferably 10 meters.

Measuring at 10 meters means that you’re measuring at least 1 wavelength away (some people’s rule of thumb definition of the beginning of the far field region) at a frequency of 30 MHz which is often the lower end of the measurement range. This means that for the most part, they’re measuring the electric field strength of a stable wave in the far field.

Absolute vs. Relative Measurements

Making relative measurements with equipment like near field probes can be useful for EMC troubleshooting, but it doesn’t give us a decent idea of whether our product will pass at a lab.

Full compliance EMC test labs can spend hundreds of thousands of dollars on EMC test equipment to be able to get accurate and repeatable measurements as well as create accurate and repeatable immunity test levels.

At a full compliance facility the measurements are absolute field strength values measured at a particular separation between the EUT and antenna.

What Makes a Full Emissions Compliance Test Site Accurate?

QAI 10m OATS Vancouver

If we want to make accurate pre-compliance emissions measurements, we need to know what an ideal test site looks like and what the characteristics are that we ideally want to copy.

Here is an outline of the main equipment and facilities of a full compliance lab that help them to meet the +/- 4 dB error budget.

EMI Test Site/Area

The way in which an emissions test site is constructed has a huge bearing on the potential accuracy of the measurements. Below I’ll go into the important factors of designing an accurate test site.

Open Area Test Site (OATS)

The properties of an open area test site that allow it to meet the +/- 4dB error budget are:

It’s important to keep a large clearance between test area and RF reflective (metallic) objects to ensure that the contribution of reflections received by the antenna are negligible.

The measurement antenna actually receives a field directly from the EUT plus a reflection off the ground plane. It’s important that this ground plane is flat so that the reflection is predictable and we can account for it when making measurements.

As mentioned above, it’s important to be in the far field, or close to it, to make accurate repeatable measurements. At 30 MHz, one wavelength is 10m and at 100 MHz one wavelength is 3m. At closer measurement distances, you enter the near field and measurements get much less accurate.

Semi-Anechoic Chamber (SAC)

When you’re using a semi-anechoic chamber, there are a few important factors to consider.

A chamber essentially a sealed metal room with RF absorbers lining the inside.

QAI 3m Semi-Anechoic Chamber Vancouver

The dimensions of the chamber itself can affect the measurement and the dimensions are influenced by the standards that you want to comply with. You would want to look for the size of chamber called out in the standard that applies most commonly to your product.

Here are some more variables of semi anechoic chambers that influence measurement accuracy:

This comprehensive guide to anechoic chambers from ETS Lindgren goes into much more detail on this subject.

Full Compliance Test Equipment

As well as a well designed measurement area, to meet the +/- 4 dB error budget EMC test labs also have to invest in accurate measurement devices and transducers.

Spectrum Analyzer/EMI Receiver

If your spectrum analyzer doesn’t have all of the bandwidth options that are called out in the applicable standards, this is likely going to add a few dB to your error budget.

Antenna(s)

Of course the measurement antenna plays a key role in measurement accuracy. The gain of antennas varies with frequency, so you need to know what the gain is at many points across the spectrum of interest. Antennas must be individually calibrated to get the exact antenna factors needed to extrapolate from the raw measurement values to an accurate field strength measurement. Otherwise the raw data you see on your spectrum analyzer is virtually meaningless.

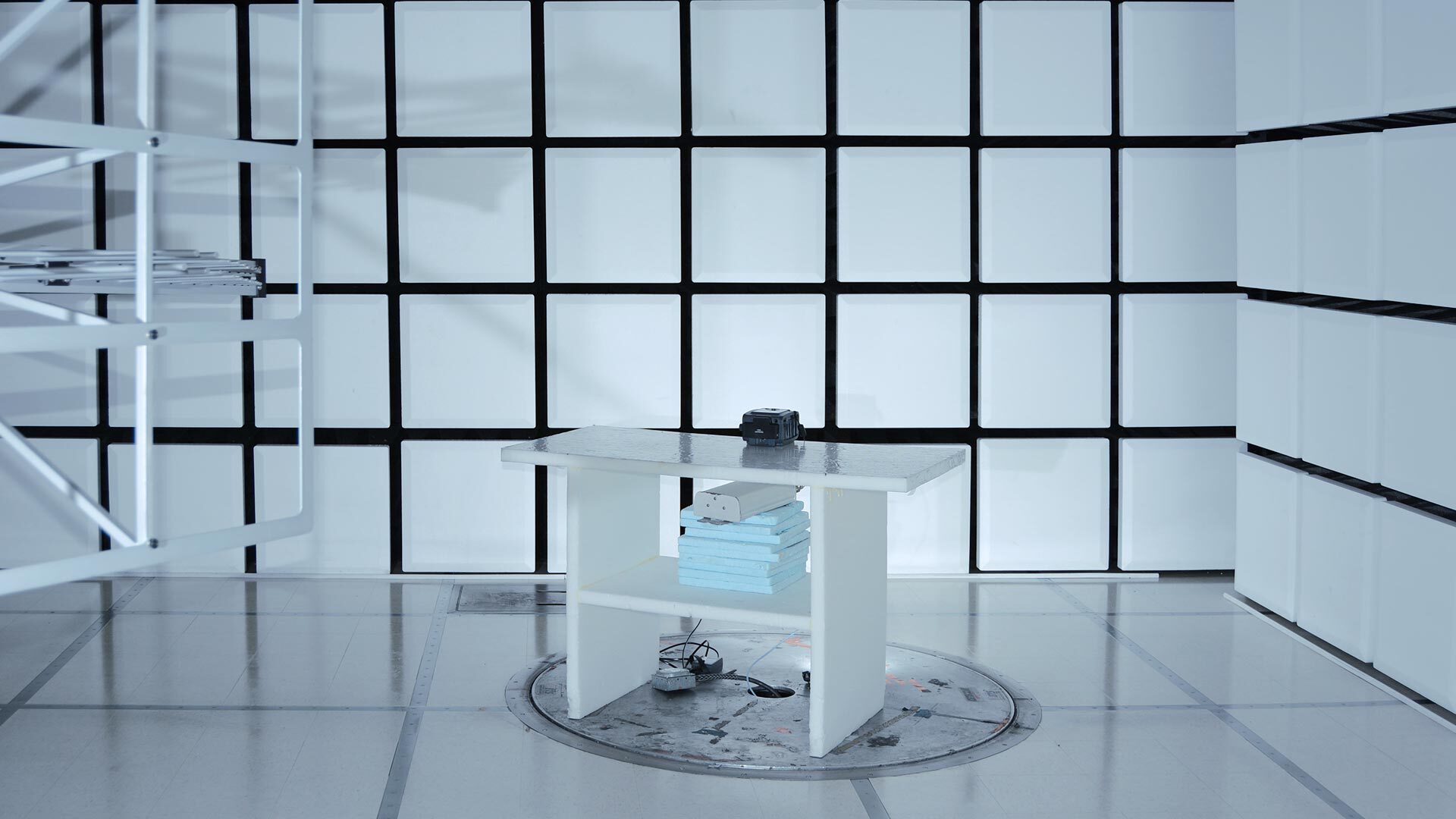

Turntable

Antenna Mast

In the same way, the maximum field strength at the antenna will be at some particular height. A full compliance test lab needs to move the antenna up and down a 4 or 6 meter antenna mast to make sure it has found the point where the field strength is at a maximum. Again, moving the antenna up and down can easily see measurement difference of several 10’s of dBs. If your pre-compliance test setup does not have a movable antenna mast, that’s also going to increase your error budget significantly.

Cable

The cable from the measurement antenna to the spectrum analyzer/receiver is also a ‘transducer’. The attenuation of the cable varies with frequency and can easily attenuate your signal by several dB at higher frequencies. It’s important to calibrate your cables so that you know how much signal is being lost at every point across the band of interest. For your pre-compliance setup, I’d recommend buying a cable that comes with calibration data, or calibrating it yourself with a network analyzer (or signal generator + spectrum analyzer).