Embodied carbon что это

Embodied carbon: What it is and how to tackle it

For years, developers and contractors have been aware of a building’s operational carbon emissions when developing new sites. Responsible for most of the total emissions over an asset’s lifetime, they have been a priority for carbon reduction targets to date. But to become carbon neutral and deliver net zero buildings, the same level of focus and investment is needed to tackle embodied carbon emissions.

Quick links

Addressing embodied carbon

Embodied carbon refers to the emissions during the construction of a building rather than when it is in use – or the carbon footprint of a material. With the pressure on to decarbonise the built environment and deliver carbon neutral buildings ahead of the government’s 2050 deadline, it’s becoming increasingly important for contractors and developers to tackle it appropriately. Some local authorities have also started to ask about the embodied carbon footprint of new developments, so understanding what it is and how to reduce it will be vital for projects moving forward.

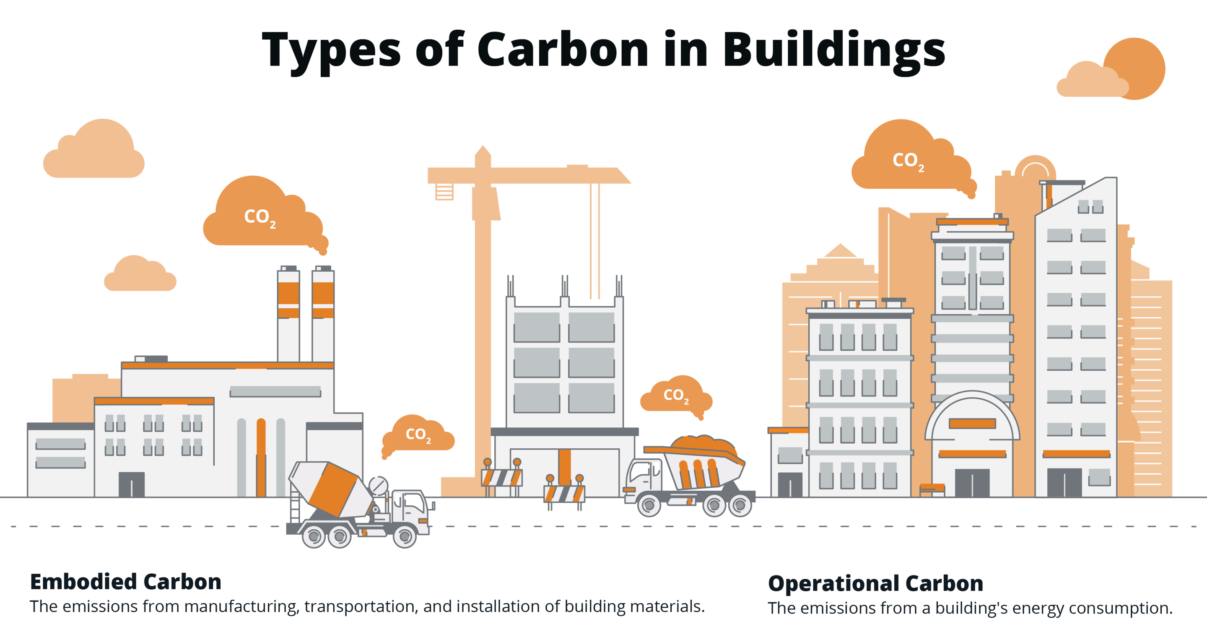

Embodied carbon vs operational carbon

Embodied carbon

Embodied carbon is the amount of carbon emitted during the construction of a building. The extraction of raw materials, the manufacturing and refinement of materials, transportation, installation and disposal of old supplies can all produce embodied carbon emissions. Essentially, embodied carbon is built into the fabric of building.

Operational carbon

Operational carbon is the amount of carbon emitted once a building is in use. It’s easier to measure than embodied carbon and has been a reduction priority for a while now. The aim is to retrofit existing structures and design new buildings with energy efficient practices, including monitoring and lowering the emissions from heating, cooling, and the management and maintenance of a product or structure.

Why tackle embodied carbon

Developing net zero carbon assets requires driving down embodied carbon to an absolute minimum. As companies commit to net zero pathways for their own emissions, they are now focusing on reducing the carbon footprint of what they build. Less embodied carbon will mean a lower requirement for carbon sequestration. This is a vital step in reaching global emissions reduction targets.

Reducing embodied carbon should be a priority for developers and contractors for many other reasons: legal limits on embodied carbon will be mandated, using fewer resources can reduce costs and risk around resource availability, and it may be a requirement to obtain planning permission in the future.

Regulating embodied carbon

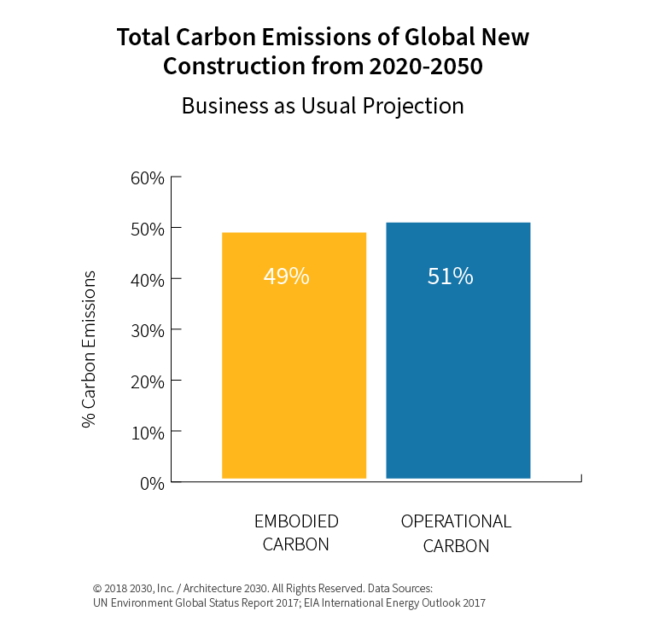

Embodied carbon has moved a lot higher up the agenda for industry and government. While it currently accounts for 11% of greenhouse gas emissions, with the projected increase of construction initiatives over the coming decades, it’s believed that by 2050 embodied and operational carbon emissions will be the same.

Industry leads are currently backing proposals for legal limits on embodied carbon. This would see an amendment to the Building Regulations known as “Part Z” which would enforce:

Building for resilience

One of the main methods to reduce embodied carbon is by using more resilient materials that will last longer and are often produced via a more efficient construction process. Adopting these changes will reduce capital expenditure as well as maintenance, repair and replacement costs.

Embodied carbon and planning consent

BREEAM, LEED and Green Star are all building rating systems that recognise embodied carbon measurement and mitigation as part of minimising the impact of a building’s life cycle.

Embodied carbon что это

Мы используем файлы cookies для улучшения работы сайта НИУ ВШЭ и большего удобства его использования. Более подробную информацию об использовании файлов cookies можно найти здесь, наши правила обработки персональных данных – здесь. Продолжая пользоваться сайтом, вы подтверждаете, что были проинформированы об использовании файлов cookies сайтом НИУ ВШЭ и согласны с нашими правилами обработки персональных данных. Вы можете отключить файлы cookies в настройках Вашего браузера.

Глава

Embodied carbon and trade competitiveness in Russia

В книге

В рамках современной системы международного климатического регулирования страны несут ответственность за выбросы парниковых газов, осуществляемые в результате хозяйственной деятельности на их территории, даже в том случае, если эмиссия происходит при производстве продукции, направляемой на экспорт. Напротив, импорт углеродоемкой продукции международными соглашениями никак не ограничивается.

В данной работе на основе анализа межстрановых таблиц «затраты-выпуск», представленных в базе данных WIOD, осуществлена оценка объема выбросов углекислого газа, осуществляемых при производстве продукции, экспортируемой Россией за рубеж («экспорта выбросов») и импортируемых в Россию из других стран («импорта выбросов»). Выявлено, что Россия является вторым в мире нетто-экспортером выбросов углекислого газа, причем подавляющее большинство выбросов направляется в форме экспортируемой продукции в развитые страны. Причинами высокой углеродоемкости российской экспортной продукции являются как технологическая отсталость от развитых стран, так и особенности товарной структуры внешней торговли России: ее экспорт состоит преимущественно из углеводородного сырья и энергоемких товаров, а импорт – из продукции с относительно невысокой энергоемкостью.

Значительные объемы нетто-экспорта выбросов делают Россию страной, интересам которой текущая схема учета выбросов отвечает в наименьшей степени. С одной стороны, Россия, как и другие крупные страны-нетто-экспортеры выбросов, заинтересована в пересмотре принципов распределения ответственности между производителями и потребителями углеродоемкой продукции. С другой стороны, существующая технологическая отсталость делает ее уязвимой перед лицом политики «углеродного протекционизма», которая может начать применяться в других государствах.

В рамках современной системы международного климатического регулирования страны несут ответственность за выбросы парниковых газов, осуществляемые в результате хозяйственной деятельности на их территории, даже в том случае, если эмиссия происходит при производстве продукции, направляемой на экспорт. Напротив, импорт углеродоемкой продукции никак не ограничивается международными соглашениями, включая Парижское соглашение, принятое в 2015 г. В данной работе на основе анализа межстрановых таблиц «затраты-выпуск». Выявлено, что Россия является вторым в мире нетто-экспортером выбросов углекислого газа, причем подавляющее большинство выбросов направляется в форме экспортируемой продукции в развитые страны. Значительные объемы нетто-экспорта выбросов делают Россию страной, интересам которой текущая схема учета выбросов отвечает в наименьшей степени. С одной стороны, Россия, как и другие крупные страны-нетто-экспортеры выбросов, заинтересована в пересмотре принципов распределения ответственности между производителями и потребителями углеродоемкой продукции. С другой стороны, существующая технологическая отсталость делает ее уязвимой перед лицом политики «углеродного протекционизма», которая может начать применяться в других государствах.

The paper is organized as follows: section 1 describes the Russian official input-output tables, which is the key data source; section 2 contains an overview of processing of the source data into a form corresponding to the GTAP requirements; section 3 outlines how we split the source 2003 I-O table; section 4 follows steps of reconciling Russian data with the GTAP structure. Section 5 is focused on imports and tax tables creation. Section 6 notes diagnostics tests applied to the data base before its distribution.

Предлжена модель глобального равновесия, основанная на концепциях мультипликатора Кейнса и Леонтьева

What is Embodied Carbon?

Embodied carbon is the carbon dioxide (CO₂) emissions associated with materials and construction processes throughout the whole lifecycle of a building or infrastructure.

It includes any CO₂ created during the manufacturing of building materials (material extraction, transport to manufacturer, manufacturing), the transport of those materials to the job site, and the construction practices used.

Put simply, embodied carbon is the carbon footprint of a building or infrastructure project before it becomes operational. It also refers to the CO₂ produced maintaining the building and eventually demolishing it, transporting the waste, and recycling it.

Embodied carbon is distinct from operational carbon — the carbon that comes from energy, heat, lighting, etc. Thanks to advances in reducing operational carbon, recent data from the World Green Building Council indicates that embodied carbon is becoming a larger portion of a building’s overall carbon footprint.

Why Embodied Carbon is a Focus in Construction

The world’s building stock is expected to double by 2060 — that’s equivalent to adding an entire New York City to the planet every month for the next 40 years.

This is good news for concrete producers. However, without some changes in how we produce concrete, it’s bad news for climate change. Cement — the key ingredient that gives concrete its strength — is also one of the largest emitters of CO2 in the built environment.

Since concrete is the most abundant human-made material in the world, cement production creates

7% of the world’s CO2 emissions and is the largest contributor to embodied carbon in the built environment.

Tackling Embodied Carbon

Embodied carbon is expected to account for nearly 50% of the overall carbon footprint of new construction between now and 2050.

To address embodied carbon, a number of organizations including Architecture 2030, Structural Engineers 2050 Challenge (SE2050), the Carbon Leadership Forum, and the World Green Building Council have jointly taken on a mission to eliminate embodied carbon from buildings by the year 2050.

One of the simplest ways to move the needle on embodied carbon is to change the way concrete is specified. Watch our on-demand webinar, The Case for Performance-Based Concrete Specs, to learn more.

Embodied Carbon

Embodied carbon emission is the carbon dioxide produced in the making of a building upfront.

Related terms:

Sustainability and life assessment of high strength natural fibre composites in construction

21.4.3 Data generated from life cycle assessments

The data measured in an LCA are summarized to give a more detailed description of the environmental impact. The importance and impact of the data are explained and also illustrate how it is measured and what the metric of measurement is.

21.4.3.1 Embodied carbon

Embodied carbon is the carbon dioxide (CO 2) or greenhouse gas (GHG) emissions associated with the manufacture and use of a product or service. For construction products, this means the CO2 or GHG emission associated with extraction, manufacturing, transporting, installing, maintaining and disposing of construction materials and products. The majority of embodied carbon for a construction product is CO2 emitted from the use of fossil fuels in extraction and manufacturing of construction materials and as a result of process emissions from manufacturing.

21.4.3.2 Acidification

Acidic gases such as sulphur dioxide (SO2) react with water in the atmosphere to form ‘acid rain’, a process known as acid deposition. When this rain falls, often a considerable distance from the original source of the gas, it causes ecosystem damage of varying degrees, depending upon the nature of the landscape ecosystems.

21.4.3.3 Eutrophication

Nitrates and phosphates are essential for life, but the increased concentrations in water can encourage excessive growth of algae and reduce the oxygen within the water. Eutrophication can therefore be classified as the overenrichment of water courses. Its occurrence can lead to the damage of ecosystems, increasing mortality of aquatic fauna and flora and to loss of species dependent on low-nutrient environments. This leads to an overall reduction in the biodiversity of these environments and has knock-on effects on nonaquatic animals and humans who rely on these ecosystems.

21.4.3.4 Stratospheric ozone depletion

Ozone-depleting gases cause damage to stratospheric ozone or the ‘ozone layer’ by releasing free radical molecules, which breakdown ozone (O3). Damage to the ozone layer reduces its ability to prevent ultraviolet (UV) light entering the earth’s atmosphere and increases the amount of carcinogenic UVB light hitting the earth’s surface. This in turn results in health problems in humans such as skin cancer or cataracts and sun-related damage to animals and crops. The major ozone depleting gases are CFCs, HCFCs and halons. Growing concern in the 1980s led to worldwide efforts to curb the destruction of the ozone layer, culminating in the Montreal protocol, which banned many of the most potent ozone-depleting gases.

21.4.3.5 Photochemical ozone creation

In atmospheres containing nitrogen oxides (NOx), a common pollutant, and volatile organic compounds (VOCs), ozone and other air pollutants can be created in the presence of sunlight. Although ozone is critical in the high atmosphere to protect against UV radiation, low-level ozone is implicated in impacts as diverse as crop damage and increased incidence of asthma and other respiratory complaints.

21.4.3.6 Abiotic depletion

Abiotic depletion indicators aim to capture the decreasing availability of nonrenewable resources as a result of their extraction and underlying scarcity. As implied in the earlier titles, there are several different versions of abiotic depletion covering either all nonrenewable resources or more particular resources such as scarce elements/ores or nonrenewable fuels.

21.4.3.7 Raw material use/mineral extraction

‘Raw material use’ takes account of the use of all renewable and nonrenewable resources, while ‘mineral extraction’ accounts for all virgin mineral material consumed in a process/product/project, eg, the extraction of aggregates, metal ores and minerals.

21.4.3.8 Toxicity

Toxicity indicators aim to quantify the degree to which a particular substance causes damage to living organisms. There are a number of different indicators that indicate toxicity to different groups of organisms in different ecosystems. Assessments of toxicity are based on guidelines for tolerable concentrations in air and water, tolerable daily intake and acceptable daily intake for human toxicity. Substances that generally have the highest impacts in toxicity categories include heavy metals such as mercury or chromium and aromatic hydrocarbons (substances with a benzene ring). It should be noted that indoor air quality and its effect on human health is not covered by this category, but they are sometimes accounted for in a separate ‘indoor air quality’ category.

21.4.3.9 Land use

The way that land is used and the way that land use changes over time have significant implications on ecosystems, landscapes and the environment. Changes in the qualities of the soil in terms of nutrient content, pH, soil depth (ie, due to erosion) or water filtration have knock-on effects on biodiversity, food production and land values. Therefore land use is a true sustainability issue as it covers social, economic and environmental issues.

21.4.3.10 Embodied water

Fresh water resources are coming under increasing pressure from population growth, rising per capita water use, urbanization and increased industrial activity and the effects of climate change. Embodied water begins to consider the effect of man’s activities on water, for example, in reducing availability.

Sustainable Construction Materials

3.10 Embodied Carbon

Although embodied energy and embodied carbon are directly related, the impact of any material on resource depletion and on green house gas emissions may be very different. It will depend upon the primary fuel consumed and the means of generation of electricity. Consumption of renewable energy may be considered to have zero emissions provided the embodied energy of the collectors and generators are neglected. Similarly nuclear energy will also have zero carbon emissions. The embodied carbon is therefore dependent upon the fuel mix in the location where the processing takes place.

Some materials can even be considered as having negative embodied carbon when carbon sequestered during their growth has been accounted for. Trees and short term crops used for building materials sequester atmospheric carbon dioxide during their growing period, the weight of which may be greater than the emissions produced during manufacture.

Low clinker cement as a sustainable construction material

17.6.4 Emissions associated with silica fume

Data on the embodied carbon of silica fume is hard to find. King (2012) reported a value of 0.014 tonne CO2eq/tonne of slurry, which equates to 0.028 tonne CO2eq/tonne for silica fume. This value includes production of the silica fume and slurry mixing in Norway plus transport to the United Kingdom. As with PFA, the virtual water of silica fume, while unreported, is unlikely to be great.

With replacement levels of 10% or less, the replacement of cement with silica fume will not achieve significant reductions in the embodied carbon of any concrete, 10% at best. However, the environmental benefits arise when considering the whole-life performance of a concrete structure. The replacement of cement with silica fume brings two possible environmental benefits. Firstly, durability is improved, so the environmental impacts of repair or maintenance are reduced. Secondly, as mentioned previously, the addition of silica fume to concrete can improve strength by 30–50%, facilitating the production of high-strength concrete. This, in turn, means less concrete is used. However, the potential improvements in environmental footprints become project-specific, thus are beyond the remit of this section.

24th European Symposium on Computer Aided Process Engineering

3.2 Embodied Carbon Impact

This metric accounts for the embodied carbon of the resource exchanged between participants i and j. Re-used and recycled materials have lower embodied carbon, hence lower impact. It uses quantities Qi,j of exchanged resources, embodied carbon value of the resources ECi,j and the credit price of carbon dioxide C O 2 p as formed by the carbon trading scheme:

Sustainability of natural stone as a construction material

12.4.2 EE and carbon footprint of stone

Much of the EE/EC footprint of natural dimension stone is due to the processing of the blocks after extraction, and there remains ample scope to reduce the current figures further: Some 90–95% of the EC associated with dimension sandstone was shown by Crishna et al. (2011) as being due to the processing alone. Renewably powered processing facilities could drive stone’s EE/EC footprint down to incredibly low levels.

Natural stone has a low EE and carbon footprint ( Tables 12.3 and 12.4 ). However, objective comparison between materials of different build contexts is difficult: Masonry materials tend to be used in heavy constructions, whilst the materials associated with higher EE/EC footprints tend to be lighter. This difficulty is resolved by the LCA for the structures respectively, although a feel for comparative purposes can be gained by comparing constructions in the BRE’s Green Guide ( Anderson et al., 2009 ). The context of use issue is well represented in slate; whilst there are exceptions in which it is used in structural walling, its predominant application is as a roofing material. Therefore, a unit area assessment of the EE/EC footprint would be in order.

| Embodied carbon of dimension stone (cradle-gate) | ||||

|---|---|---|---|---|

| Source | Sandstone (kgCO2/t) | Limestone (kgCO2/t) | Granite (kgCO2/t) | Slate (kgCO2/t) |

| Hammond and Jones (2008) a | 60 | 90 | 70 | 7–63 |

| Crishna et al. (2011) | 64 | – | 93 | 232 |

| University of Tennessee b | – | 105 | 62 | 28 |

| Embodied energy of dimension stone (cradle-gate) | ||||

|---|---|---|---|---|

| Source | Sandstone (MJ/t) | Limestone (MJ/t) | Granite (MJ/t) | Slate (MJ/t) |

| Hammond & Jones ICE | 1000(?) | 410 | 4100 | 30–1400 |

| University of Tennessee | a | 964 | 5908 | 208 |

The data pool for the EE and carbon environmental impact of natural dimension stone was noted by the source authors to be small, leading to the relatively high deviation observed. The figures quoted in Tables 12.3 and 12.4 are largely composed of the energy (and related CO2 impact) in the processing of the quarried stone. The EE figures do not appear to accord well with the EC figures, across the few sources available. The figures indicated consider the ‘waste’ associated with the final product (dimension stone), which is very high for slate. However, Crishna et al. (2011) observe that, owing to the zero waste in practice arising from stone quarries, considering the environmental footprint of stone on the total material produced (including secondary products of rubble and hardcore, etc.), slate can be demonstrated to have lesser carbon impact than the other building stones.

Interpreting the data generally, taking average values across the different sources, it is clear that natural stone exhibits a low environmental footprint when compared with other typical building materials ( Table 12.5 ).

| Material | Embodied carbon (kgCO2/t) |

|---|---|

| Aluminium (general) | 8240 |

| Cladding panel (fibre-cement, colour-coated) | 1280 |

| Concrete (RC28/35) | 139 |

| Conc. block: 8 MPa | 59 |

| Conc. block: 13 MPa | 100 |

| Conc. block: AAC | 240–375 |

| Brick: Facing | 520 |

| Brick: General | 230 |

| Glass (toughened) | 1350 |

| Steel: General | 1460 |

| Steel: Plate | 1660 |

| Steel: Section | 1530 |

| Timber: Hardwood | 470 |

| Timber: Softwood | 450 |

| Sandstone a | 62 |

| Limestone a | 98 |

| Granite a | 75 |

| Slate a | 96 |

Note: All UK values.

The mortar with which the stone is laid represents a major constituent in the bulk of a stonework wall, particularly where the masonry units are small (demanding a higher frequency of joints, as in brickwork). Traditionally, stone masonry was laid with lime mortar. As with natural stone, the data pool for lime mortars is correspondingly small, and some contention is to be found in the literature as to its environmental footprint relative to cement mortar (eg, Hammond and Jones, 2008; De Vekey, 2005; Reddy and Jagadish, 2003 ).

The lower burning temperature of lime does not necessarily or directly constitute an environmental saving, owing to the typically longer burning durations. However, lime mortars feature a carbonation set, which reabsorbs an extent of the CO2 driven off when the limestone is burned. This is especially so for putty limes, which set entirely by carbonation and fully reabsorb the displaced CO2; the low end of the natural hydraulic lime (NHL) (eg, NHL 2) similarly exhibit a high degree of carbonation. Little difference is observed between NHL 3.5 and NHL 5 mortars in terms of their respective proportion of carbonation set ( Hughes and Swann, 1998 ). The formation of the compound which demands the carbonation set (portlandite) is strongly influenced by the phase chemistry, but in general terms the lower the burning temperature, the higher the proportion of portlandite formed and available for carbonation. For the more hydraulic mortars (NHL 3.5, NHL 5 and cements), the mineralogy and higher burning temperatures lead to smaller proportion of portlandite formed, and consequent carbonation is small if at all. Carbonation is a complex process related to available portlandite, diffusivity of the pore matrix and environmental conditions.

Given the foregoing, support is made for the use of the weaker, high-carbonation limes. Reddy and Jagadish (2003) observe that lime:pozzolana mortars have the lowest environmental impact of all the building mortars they studied, including cementitious. Table 12.6 abstracts from Hammond & Jones Inventory of Carbon and Energy (ICE) the data for cement mortar, and the closest available mixture to represent a lime mortar.

| Characteristic | Lime (L:A) | Gauged lime (C:L:A) 1:2:9 | Cement (C:A) (1:3) |

|---|---|---|---|

| Embodied energy (MJ/t) | – | 1030 | 1330 |

| Embodied carbon (kgCO2/t) | – | 145 | 208 |

Data from Hammond & Jones ICE.

Appraising the difference between cradle-to-gate and cradle-to-site across the stones is made difficult owing to the single data source available. However, Table 12.7 allows comparison between stone sourced nationally and imported stone from abroad. The imported figures quoted were derived by Crishna et al. (2011) assuming the shortest/most practicable route, and that processing was undertaken in the country of origin.

| Embodied carbon of imported dimension stone (cradle-site) | ||||

|---|---|---|---|---|

| Country of origin | Sandstone (kgCO2/t) | Limestone (kgCO2/t) | Granite (kgCO2/t) | Slate (kgCO2/t) |

| UK | 77.30 | – | 158.00 | 297.40 |

| Spain | 134 | – | 161 | 318 |

| Poland | – | – | 188 | – |

| India | 312.30 | – | 336.50 | – |

| China | 504.00 | – | 415.50 | 568.10 |

Data from Crishna, N., Banfill, P., Goodsir, S., 2011. Embodied energy and CO2 in UK dimension stone. Resour. Conserv. Recycl. 55, 1265–1273.

The environmental footprint of stone increases many times over the further away the source is located. Clear suppport for the use of indigenous stone is demonstrated in EE and carbon terms, aside from the less-quantifiable sustainability benefits of promoting local rural employment, and safeguarding local distinctiveness.

Application of nanomaterials in alkali-activated materials

5.6 Effects of carbon nanotube on alkali-activated materials

As novel class of low- embodied carbon binders, alkali-activated binders have attracted great attention in the recent years, however their fracture energy is in general much less than that of Portland cement ( Pan et al., 2011 ). Various efforts have been spent on searching appropriate reinforcing methods for alkali-activated materials to make them more practically applicable, including for instance steel fiber, polypropylene fiber, and basalt fibers ( Khater and El Gawaad, 2016 ). Carbon nanotube has been widely applied for various applications since its discovery ( Lijima, 1991 ), thanks to its excellent properties, including high strength and Young’s modulus. The excellent mechanical properties of carbon nanotube make it a very attractive reinforcing agent for brittle matrix like cement and recent studies on reinforcing alkali-activated materials with carbon nanotube has also drawn increased attention.

Saafi et al. (2013) investigated the multifunctional properties of carbon nanotube reinforced fly ash geopolymer. Low calcium fly ash was used as the solid precursor and NaOH modified Na2SiO3 as the alkali activator. The used multiwalled carbon nanotube was synthesized with chemical vapor deposition method, showing an outer diameter of 30–50 nm and a length of 10–20 μm. Glenium 51 superplasticizer was used as a surfactant to better disperse the carbon nanotube that is added up to 1% by mass with an interval of 0.2%. SEM images (see Fig. 5.11 ) show that the nanocomposites containing MWCNTs of 0.1% and 0.5% by mass displayed a good dispersion where the individual MWCNTs were spread throughout the geopolymer matrix with a uniform density, which is also partly attributed to the effect of the NaOH alkaline solution. Nevertheless, it is evident that the NaOH solution was not sufficient to disperse well the MWCNTs at 1% by mass, reflected by the significant agglomerations in the alumina–silicate gel.

The results of mechanical properties show that the carbon nanotube contributes to enhanced flexural strength and Young’s modulus and 0.5% dosage shows the optimal improvement, attributed to the microcrack bridging effect. Furthermore, the carbon nanotube contributes to enhanced electrical conductivity up to the dosage of 0.5%.

Rovnaník et al. (2016) studied the effect of carbon nanotube on the mechanical fracture properties of fly ash geopolymer. Low calcium fly ash was used as the solid precursor and sodium silicate solution with a SiO2/Na2O molar ratio of 1.6 is used as the alkali activator. Multiwalled carbon nanotube was added with the mass ratio of 0.05%, 0.1%, 0.15%, and 0.2%, respectively. Compressive strength, modulus of elasticity, fracture toughness, and fracture energy were determined. The results show that the added carbon nanotube has an enhancement effect on compressive strength and modulus of elasticity and the optimal dosage is 0.15%. However, the carbon nanotube shows negative effect on the fracture toughness and fracture energy.

Abbasi et al. (2016) investigated the microstructure and mechanical properties of a metakaolinite-based geopolymer reinforced with carbon nanotube. Kaolin was used as the solid precursor and aqueous sodium silicate solution modified with sodium hydroxide as the alkali activator. Multiwalled carbon nanotube with a surface area of 250–280 m 2 /g, inner diameter of 10–20 nm, and length of 10 μm was used with the dosages of 0.5% and 1%, respectively. SEM analysis shows that the added MWCNTs possess good microcrack bridging capacity and many MWCNTs are involved in bridging the microcrack, implying a good bonding between the MWCNT surfaces and the surrounding geopolymer paste. Mechanical strength results show that the addition of carbon nanotube enhances both the compressive and flexural strength while the enhancement on flexural strength is more significant. 0.5% of addition shows the best enhancement effect which might be explained by the agglomeration of carbon nanotube in the case of 1% addition.

Stabilised soil blocks for structural masonry in earth construction

Abstract:

Stabilised soil blocks (SSBs) are energy efficient and low embodied carbon alternative materials for structural masonry. there is an upsurge of interest among building professionals in utilising low embodied carbon materials. This chapter deals with various aspects of SSBs applicable to structural masonry. A brief outline of soil classification and developments in SSB technology is provided. different methods of soil stabilisation and production techniques for SSBs are discussed in detail. The influence of soil composition on SSB characteristics and optimum soil grading for the production of SSBs are discussed. the role of block density, moulding moisture content and stabilisers on various SSB characteristics including durability aspects is illustrated. The chapter ends with a discussion of the behaviour of SSB masonry, guidelines for SSB masonry design and some short case studies.

Assessment of the energy and carbon embodied in straw and clay masonry blocks

Abstract

The manufacturing of wall blocks with straw and clay by small enterprises is introduced, and energy and carbon embodied is assessed. These ecological burdens are compared to fired clay bricks and concrete blocks commonly used in the region of study. The technique has been used to build houses and large public buildings. It comprises the advantages of using local materials and working force with the addition of improved thermal efficiency. The benefits of constructions with renewable and local resources include social benefits from local labor and businesses; lower impacts and recycling at construction and demolition; increasing resilience; adaptation of materials and techniques to local requirements; and mitigation of environmental impacts as energy and carbon footprints. Nevertheless, the high relevance of the operational phase in buildings should be carefully considered when local renewable materials are chosen. If energy and carbon emissions during the operational phase were high, advantages of lower embodied impacts could be compensated in short periods of time. The case study shown in this chapter clearly depicts that embodied energy and carbon for straw and clay blocks are much lower than conventional fired clay bricks and concrete blocks, and provide nearly three times better thermal resistance. Even larger differences in embodied burdens are found when a layer of insulation is added to conventional walls to make the comparison on an equal thermal efficiency basis. On the other hand, when using straw, the sustainability of agricultural soils is important; this is also investigated in this chapter.

Concrete Aggregates

15.2.5 Manufactured and Recycled Aggregates

| Raw material | Treatment | Uncompacted Bulk Density (kg/m 3 ) | |||

|---|---|---|---|---|---|

| Ultra Lightweight 1700 | |||||

| Some Examples With Appropriate Bulk Density Ranges a | |||||

| Natural | Untreated | Pumice 480–880 | Colliery waste/spoil Slate waste China clay waste | Limonite, goethite 2100–2200 Magnetite, ilmenite 2600–2700 Barytes 2800 Haematite 3000 | |

| Treated | Exfoliated vermiculite (Micafil) 60–160 Expanded perlite 80–320 | Expanded clay/shale (Leca, Fibo/Liapor/ Sintag) 380–720 Diatomite 450–800 Sintered colliery waste 550–900 Expanded slate (Liapor) 560–860 | |||

| Manufactured | Untreated | Furnace-bottom ash 720–1040 Furnace clinker or ‘cinders’ (Breeze) | Air-cooled blastfurnace slag 1000–1500 Steel slag 1600–1700 Non-ferrous slags | Ferrosilicon, ferrophos-phorus 4300 Iron or steel shot 4800 Iron or steel fragments Lead shot 8000 | |

| Treated | Expanded polystyrene 10–20 | Foamed slag 560–960 Sintered fly ash (Lytag) 770–960 Pelletised expanded slag (Pellite) 900 Sintered incinerator bottom ash | Iron separated from slag 3800 | ||

| Recycled | Untreated | Construction and demolition waste, crushed concrete, crushed masonry, crushed asphalt | |||

| Treated | |||||

29th European Symposium on Computer Aided Process Engineering

Abstract

The built environment contributes up to 50% of the UK’s carbon emissions. Most buildings’ analyses focus on the «carbon operating cost» of buildings rather than the embodied «carbon capital cost» and do not take into account a building lifespan. In this paper a new carbon accounting framework is presented modelled on financial accounting principles, with a carbon balance sheet and profit and loss. It is argued that it is illogical to discount future emissions of carbon but that it is reasonable to depreciate carbon assets and liabilities. Like Value Added Tax (VAT) accounting in financial transactions, the proposed carbon accounting method enables a proper, explicit and transparent allocation of carbon assets and liabilities to multiple agents in complex supply chains over distinct temporal, spatial and organisational boundaries.

The approach is demonstrated by applying the model to two energy-efficient buildings of the UK National Energy Foundation, a new Light-Weight building and an older High Thermal Mass one, designed for a lifespan of 50 and 150 years, respectively. The analysis shows that cement based materials, metal and insulation are the major carbon liabilities, with concrete foundations the main structural component responsible. On an operating carbon basis, the newest building produces the least CO2. In aggregate, the new building is more efficient with an annual carbon cost, including depreciated carbon capital costs, of

14 tonnes of CO2/year, vs.

21 tonnes of CO2/year for the longer lasting building. The best discounted annual capital carbon cost was for a (notional) building constructed by increasing the lifetime of the 50-year building to 150 years. However, in all buildings the discounted carbon capital cost was less than 11% of the total operating costs, showing that improvements in operating efficiency (carbon P&L) are the most important contribution to carbon emissions.